# Baby Diaper Nonwoven Fabric: Essential Material for Modern Diapers

## Introduction to Baby Diaper Nonwoven Fabric

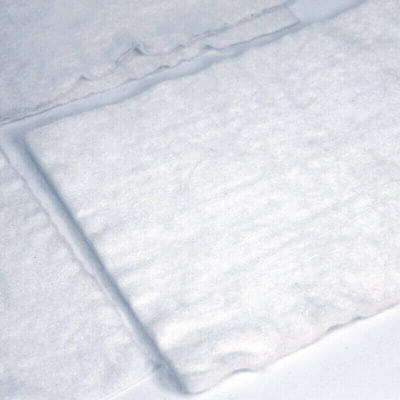

Nonwoven fabric has become an indispensable material in the manufacturing of modern baby diapers. This innovative textile offers numerous advantages over traditional woven fabrics, making it the preferred choice for diaper manufacturers worldwide. The unique properties of nonwoven materials contribute significantly to the comfort, absorbency, and overall performance of contemporary diapers.

## What Makes Nonwoven Fabric Special?

Nonwoven fabrics are engineered materials created by bonding or interlocking fibers through mechanical, thermal, or chemical processes rather than weaving or knitting. This manufacturing technique allows for:

– Superior breathability

– Enhanced softness

– Improved liquid distribution

– Better durability

– Cost-effective production

## Key Properties of Diaper Nonwoven Fabric

The nonwoven materials used in baby diapers possess several critical characteristics:

### 1. Softness and Comfort

Modern diaper nonwovens are designed to be exceptionally gentle on a baby’s delicate skin. The fibers are carefully selected and processed to create a smooth, non-irritating surface that prevents chafing and discomfort.

### 2. Excellent Absorbency

While the nonwoven layer itself isn’t the primary absorbent component (that role belongs to the superabsorbent polymer core), it plays a crucial role in quickly drawing moisture away from the skin and distributing it evenly throughout the diaper.

### 3. Breathability

High-quality nonwoven fabrics allow air circulation while preventing leaks, helping to maintain a healthier skin environment and reduce the risk of diaper rash.

### 4. Strength and Durability

Despite their lightweight nature, diaper nonwovens are engineered to withstand the stresses of active babies without tearing or breaking down.

## Types of Nonwoven Fabrics Used in Diapers

Several nonwoven technologies are commonly employed in diaper manufacturing:

### 1. Spunbond Nonwovens

Created by extruding melted polymer through spinnerets to form continuous filaments, which are then bonded together. Spunbond fabrics offer excellent strength and are often used for diaper outer covers.

### 2. Spunlace (Hydroentangled) Nonwovens

Produced by entangling fibers with high-pressure water jets, resulting in soft, cloth-like materials frequently used for diaper topsheets that contact baby’s skin.

### 3. Meltblown Nonwovens

Made by extruding molten polymer through fine nozzles while blowing hot air to create ultra-fine fibers. These are often used in combination with other nonwovens for specialized applications.

### 4. Composite Nonwovens

Combinations of different nonwoven technologies (like SMS – Spunbond-Meltblown-Spunbond) that leverage the benefits of each type for optimal performance.

## Environmental Considerations

The diaper industry continues to innovate with more sustainable nonwoven options:

– Biodegradable fiber options

– Plant-based materials

– Reduced material usage through advanced engineering

– Improved recyclability

## Future Trends in Diaper Nonwovens

Manufacturers are constantly developing new nonwoven technologies to enhance diaper performance:

– Even softer, more skin-friendly surfaces

– Enhanced breathability while maintaining protection

– Smart materials that can indicate wetness

– More sustainable production methods

– Thinner yet more effective constructions

## Conclusion

Keyword: Baby Diaper nonwoven

Baby diaper nonwoven fabric represents a remarkable marriage of textile engineering and childcare needs. Its unique properties have revolutionized diaper design, offering babies greater comfort and parents more convenience. As technology advances, we can expect even more innovative nonwoven solutions to emerge in the baby care market, continuing to improve the diaper experience for generations to come.